Traditionally, drinking water needed to be carried on board ships or vessels needed to stick close to land so fresh water could be replenished as required. The longer the voyage (or distance between freshwater sources), the more water that was required onboard. Freshwater would take between 5 and 20% of total cargo volume. How much water needed to be stocked would depend on the route taken and the number of passengers.

Shipboard Water Production

With crew, voyage lengths and ship sizes increasing, it was no longer viable to carry sufficient water onboard. When vessels switched from sail to steam power, shipboard desalination systems were installed. These desalination systems were based on single effect distillation, using thermal energy to produce water vapour from seawater. These treatment systems generated freshwater to supply drinking water for the crews and provided water for the boilers.

Since the 1980s, shipboard desalination has switched from thermal desalination to reverse osmosis (using electrical instead of thermal power to desalinate seawater). This reflects a broader trend in desalination which saw reverse osmosis supplant thermal desalination due to the lower energetic cost.

Smaller vessels like yachts also carry shipboard desalination systems, either for emergency situations (such as plastic solar stills) or for freshwater production (usually small reverse osmosis systems). These reverse osmosis systems take up very little room and can run on solar power. Moerk Water’s portable seawater desalination system runs chemical free and only requires a single solar panel to operate.

Commercial Shipboard Desalination

Cruise ships and commercial vessels have a larger requirement for freshwater than other vessels due to their size. The biggest cruise ships in the world are the two Royal Caribbean ships The Icon of the Seas and The Star of the Seas. These ships weigh almost a quarter of a million tonnes. Cruise ships will use shipboard desalination to supply drinking water for the up to 10,000 people onboard as well as for water parks and swimming pools onboard. Both Royal Caribbean ships use reverse osmosis to produce >90% of the freshwater requirement onboard. Ships of this class will often produce water at a rate of 0.5 to 2 MLD. The vessels also include advanced wastewater treatment systems comprised of bioreactors, filtration and UV disinfection units.

The biggest ship ever built was the Seawise Giant. It was constructed in 1979. Although the ship displaced 650,000 tonnes when fully loaded, it only had a crew of between 40-80 people. The shipboard desalination system only produced between 20,000 and 60,000 L/day. This reflected the smaller water footprint given the limited crew. Due to when it was built, the shipboard desalination system for the Seawise Giant was based on thermal desalination and not Reverse Osmosis.

Medical Vessel Shipboard Desalination

Medical vessels are essentially floating hospitals which serve locations not served by hospitals. These ships will anchor offshore communities and provide medical care for locals before moving to the next location. Typically, this care will include eye, dental and maternity services which all require a reliable source of freshwater. The Youth With a Mission medical ship provides medical care to remote PNG communities along the extensive inland river system. The YWAM medical ship is fitted with a Moerk Water shipboard desalination system which can treat the surrounding water and produce drinking water. The system is solar powered and maintained onboard.

Maintaining Shipboard Desalination Systems

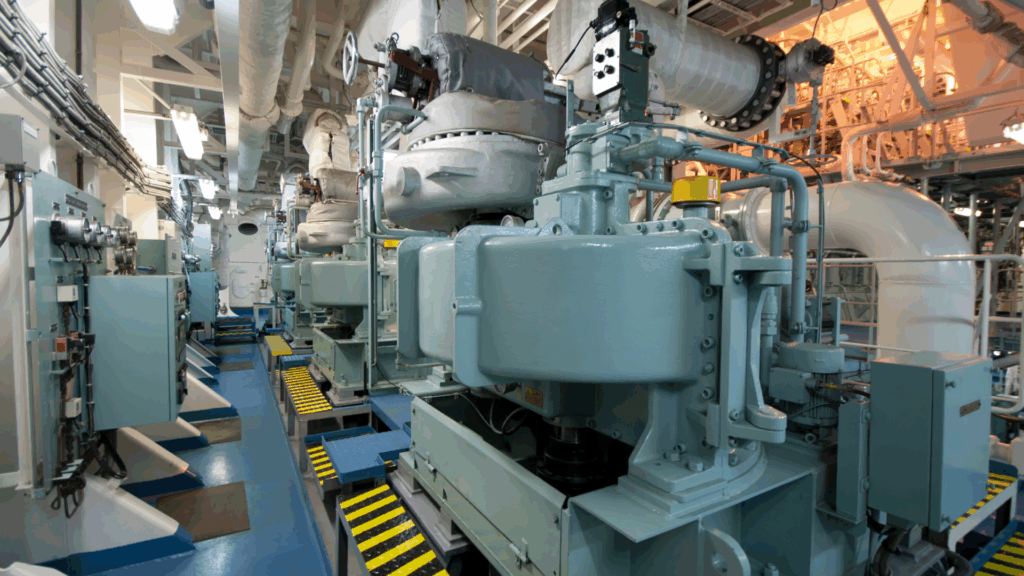

Shipboard desalination system will require a consistent source of power and ongoing maintenance. Thermal desalination systems can take advantage of the waste heat from the ships’s engines. Reverse osmosis systems will draw power from the onboard power system or can be powered entirely from solar energy.

Reverse osmosis systems are no harder to maintain than ship engines. Maintenance of the water treatment system will be covered by the maintenance schedule covering the plant room. Smaller systems, such as those on yachts, can be readily maintained by the crew. Maintenance activities will generally focus on ensuring the membrane is rinsed and preserved when not in use and ensuring correct pump operation. Given the shipboard desalination system is the sole source of freshwater generation at sea, it is important the system is designed to be reliable and built from high quality parts.

Moerk Water are experts at designing water treatment systems for shipboard desalination. Contact Moerk Water today to discuss a water treatment solution for your vessel.