Moerk Water Solution’s product line has evolved over the years as we have continually evolved it to solve our clients’ specific water challenges.

Our design process starts by understanding what the client is hoping to achieve and a general understanding of their local water situation (looking at all available water assets: be it bore, dam, soak, creek, or well, etc.). From there we complete a detailed laboratory analysis so we can prescribe the most appropriate water treatment method and system.

The resulting system design will sit in what we call the “Goldilocks Zone’ – our systems are not too big, expensive, or over-featured; while not being too small, cheap, or inadequate; our client’s find they are just the right size to meet their needs – both now and into the future. We strive to be the lowest risk, the best value, and to meet our client’s specific needs.

Our client-centric design philosophy originates from our background in international projects for remote communities that have necessitated us to build durable, low-maintenance, easy-to-service systems. Our systems are standalone, simple to operate, typically powered by renewable energy, and designed to allow for changes in raw/feedwater quality, as feedwater quality changes over time.

We communicate to clients the total upfront costs (i.e. what other infrastructure will be required for the project to operate successfully) and the ongoing costs. It is important to us that clients understand the lifetime cost of our units. There are no additional upsells or hidden costs with our systems.

The 4 Types of Water Treatment Systems

Although the treatment methodology may change, all our systems are controlled through a central operating system (HMI) which allows for the units to be fully automated and require minimal technical knowledge to operate effectively.

(1) Membrane Desalination

What is it?

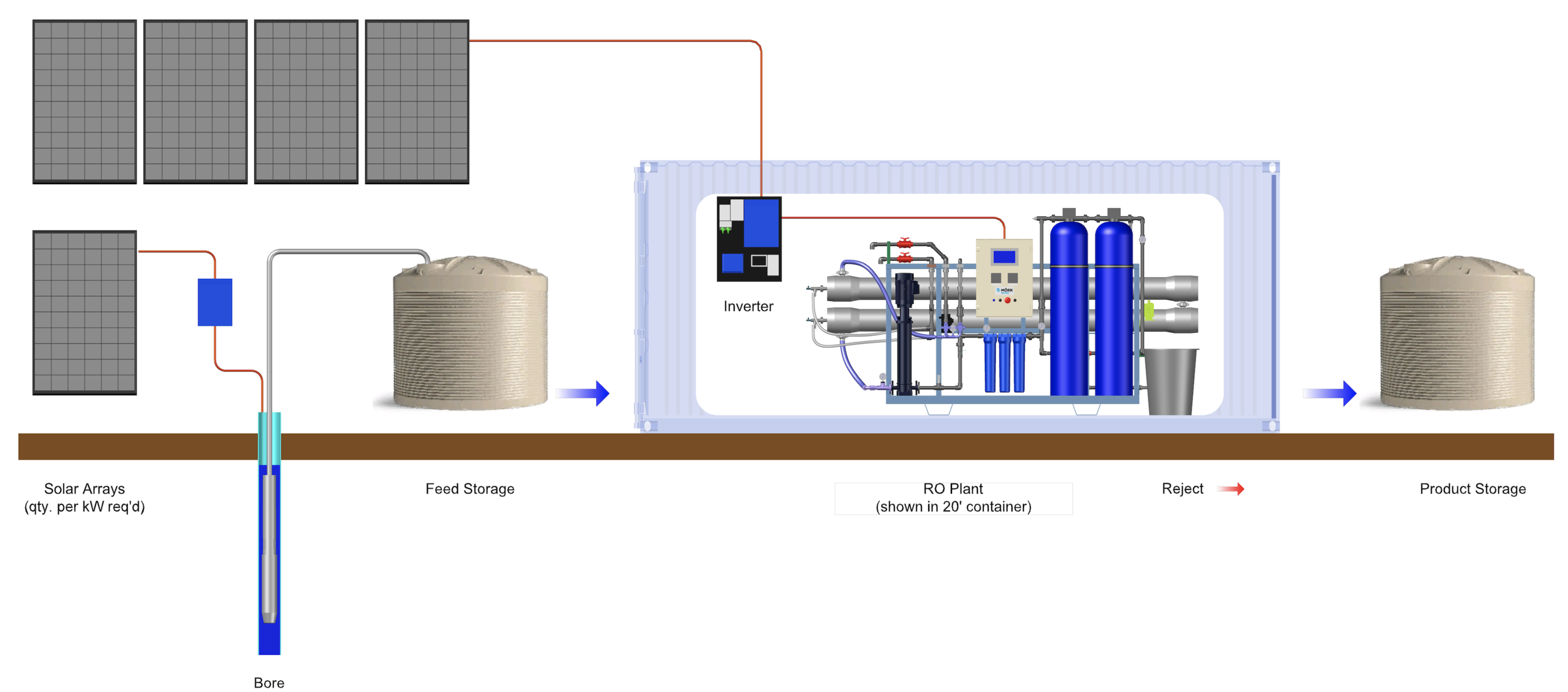

Membrane systems, like reverse osmosis (RO), are designed to remove salt and almost all other contaminants from the raw water. The technology has been around for over 40 years. That being said, the iterations of the technology have come a long way. Typically when we think of reverse osmosis we imagine large facilities that underpin a city’s water supply or small under sink units. However, in our context, we have adapted these membrane systems to be both transportable and optimised for whatever scale various agricultural and commercial concerns require.

How does it work?

The first step of a membrane system is to pre-treat the water prior to it being pumped to the membranes. Generally, this consists of simple physical treatment (aeration/filtration). Subsequently, this water is pressurised and pushed through membranes. High pressure is often required as the pores of the membranes are so small. Due to the size of the pores, the membranes are able to remove different contaminants from water. As part of the design process, we work with our clients to produce water with sufficient minerals remaining to meet their requirements (product water typically ranges from 5 to 1000 TDS). It is the most intensive and thorough water treatment method we employ however it does require more power than the other methods due to the pressure requirement. This is why solar power is often a preferred source of energy.

Here’s a general explanatory schematic to show how the typical membrane system setup works:

When should it be used?

Membrane systems are the most cost-effective way to remove salt from water. Of the technologies presented here, membranes are the only ones that can reduce the salinity of raw water, but also involve the most treatment steps. Whether the feedwater is saltier than the sea, or just too brackish to drink, membrane systems are the treatment method of choice. However, if you can get away with one of the other methods, or your operation can cope with the level of salt currently in your water, then I would first explore the other options.

(2) Batch Flocculation

What is it?

Flocculation is a chemical/physical method to reduce the dirt load in the water. Fine particles below a certain size will pass through standard filters. Following flocculation, depending on the water quality required, the water can be further purified to reduce the salt load or remove any other contaminants of concern. The advantage of a flocculation system is that it uses minimal power, the downside is it requires the ongoing use of chemicals.

How does it work?

Flocculation works by precisely dosing a chemical reagent to contaminated water, this enables the dirt particles to clump together in a larger mass called a floc. As the floc grows over time it will become heavy enough to settle to the bottom of the tank. These system need time to operate optimally and specific tanks to remove the floc at the end of the process. Clean water is then collected following floc removal.

When should it be used?

The Flocculator is the ideal solution when a water analysis reveals a high concentration of fine particles in the water. It is also an effective solution in removing high concentrations of iron. The capacity of the system scales very easily and from a CAPEX perspective it is an attractive option.

(3) Flow Disinfection

What is it?

The Flow Disinfector is the go-to solution when you are treating biologically contaminated surface water. Reverse osmosis will remove all microbiological content from the water and concentrate it into the effluent stream, and will also remove the salt. Whereas, the Flow Disinfector physically sterilises the water without removing any of the dissolved components. Water sources can easily become contaminated with a range of pathogens. It is crucial to remove the microbiological content from water, particularly if it is intended to be used for irrigation, spraying, human consumption, or watering livestock.

How does it work?

The Flow Disinfector is a two-stage physical filtration/disinfection unit. The first stage removes larger suspended solids using a media filter (that backwashes automatically). Once the suspended solids have been reduced to a specific level, then the water is sterilised by a powerful UV lamp. It is important to note that this system will not remove smaller dissolved solids like salt and that the water will need to be used soon after sterilisation as the disinfection is not persistent.

When should it be used?

This is the ideal solution for treating contaminated surface water, provided there isn’t also a salt issue. UV will significantly reduce the contaminant load. The advantage of this type of solution over other methods is the lower CAPEX and scalability. The feed pressure in the pipeline can be sufficient to move the water through the system and back-flush the media filter, further saving on capital costs.

(4) Iron Removal

What is it?

This system is primarily used to remove iron from feedwater. Iron in water can cause discolouration, bacterial contamination, and corrosion. The unit will also significantly reduce the total suspended solids in any water source. Our iron removal systems utilize physical methods to reliably remove iron from the water keeping the systems chemical-free.

How does it work?

The iron removal unit is a two-stage physical filtration unit like the flow disinfector. The first stage of the iron removal system is a bespoke aeration system which precipitates the iron out of the raw water. Following aeration, the water is passed through a filtration unit which will remove the precipitate and reduce the total level of suspended solids.

When should it be used?

Our iron removal products are typically used to treat water from bores, soaks, dams, drains, lakes, and reservoirs that have high levels of iron. Iron levels can cause a range of issues in livestock, irrigation, and spraying (by causing blockages in pipes & sprinklers). These solar-powered iron removal systems reduce the costs associated with conventional chemical treatments and eliminate the need for manual operation through sensor-based automation and can be based anywhere on a farm.

If you are interested in learning more about our systems and how they could be applied to your specific context, then…

Here’s what to do next:

For an exploratory conversation to discuss a potential water treatment project: click here to schedule a call with our team or complete the form below and we will send you an email or call you back.