Water use on mine sites

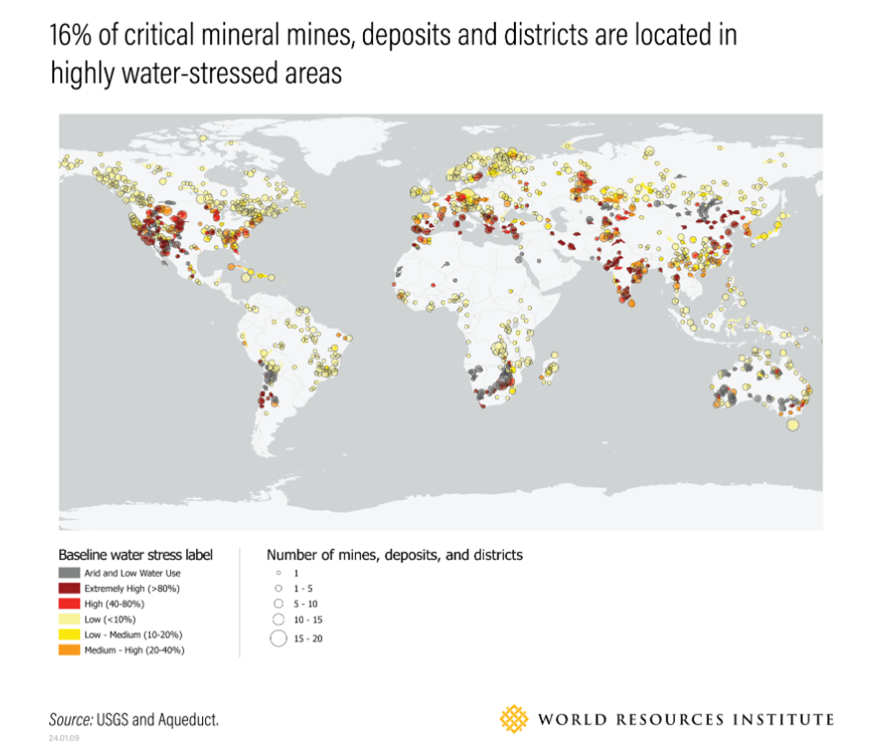

Mining activities whether mineral extraction, quarrying or petroleum/gas production are water intensive. The mining industry in Western Australia uses around 1000 GL/year of water and the wider mining industry across Australia uses over 1500 GL/year. Mine sites, particularly those focused on mineral extraction, are mostly in arid or semi-arid areas where water is scarce so mine sites will generally be forced to source their own water. The recent growth in the critical minerals sector has seen additional exploration and mine commissioning in highly water stressed areas.

In addition to extractive processes, water is used for a wide range of activities in mining as water is a relatively low-cost material that can be used widely onsite. Some examples of how water is used in mining activities include:

- Transport of ore slurries (e.g. pumping iron ore slurries through pipelines)

- Separation of minerals in chemical processes (e.g. the use of froth flotation to increase ore concentrations)

- Centrifugal separation (e.g. dewatering of muds)

- Cooling systems (e.g. onsite power generation)

- Mine dewatering (e.g. lowering groundwater level)

- Potable water for consumption (e.g. mine personnel and nearby towns)

- Dust suppression and equipment washing

Water use varies drastically from site to site. The two most important mineral commodities in Australia are coal and iron ore. There are more than 90 coal mines in Australia and 29 iron ore mines (28 of which are located in Western Australia). It takes 653 L of water to produce a tonne of coal and between 2000 L and 5000 L to produce a tonne of iron ore (at around 60% iron). Producing one tonne of gold, Western Australia’s third most valuable commodity, requires 250 million litres of water. Employees at mine sites can range from small numbers in remote exploration camps to over a 1000 at larger mine sites. All employees will require water for cooking, sanitation and drinking in addition to the water used onsite for mining activities so larger mines will require more potable water than smaller camps.

Mines will make use of any unrestricted freshwater sources close to the mine. This includes rainwater collected onsite and nearby rivers and lakes. However, the predominant source of water for mines in arid regions is groundwater. Groundwater is an obvious solution for mine sites giving mining activities involve drilling close to and beyond the water table. Groundwater quality in mine sites is often saline and contains high levels of heavy metals. Membrane based water treatment systems are used to treat this contaminated and potentially hazardous groundwater onsite to produce clean water. Water can also be produced as a by-product of mining such as with coal seam gas drilling. Any waste/excess water onsite can also be treated to a potable standard. Recycled water is currently a vastly underused commodity on mine sites. Coastal based mines (e.g. salt mines) can additionally use seawater as feedwater for a seawater desalination system.

When designing a water treatment system for a mine site multiple factors need to be considered:

- Available feedwater sources and required product water quality (determines what technologies comprises the treatment system)

- Remoteness of mine (determines need for critical spares and serviceability of plant)

- Availability of trained personnel to operate water treatment system (determines amount of automation required)

- Power requirements of treatment system (determines if additional power needs to be generated onsite)

- Disposal of waste water from water treatment process (determines available discharge methods for complying with local discharge regulations)

Moerk Water are experts at designing water treatment systems for mine sites. To discuss how you can achieve a water smart mine, contact Moerk Water today.