Wind energy has experienced remarkable growth over the last decade. However for this renewable energy system to be truly sustainable, thought needs to be given to what happens to end-of-life components. Wind Turbine sustainability therefore needs to balance growth, new technologies and methods of recycling componentry.

Growth of Wind Energy

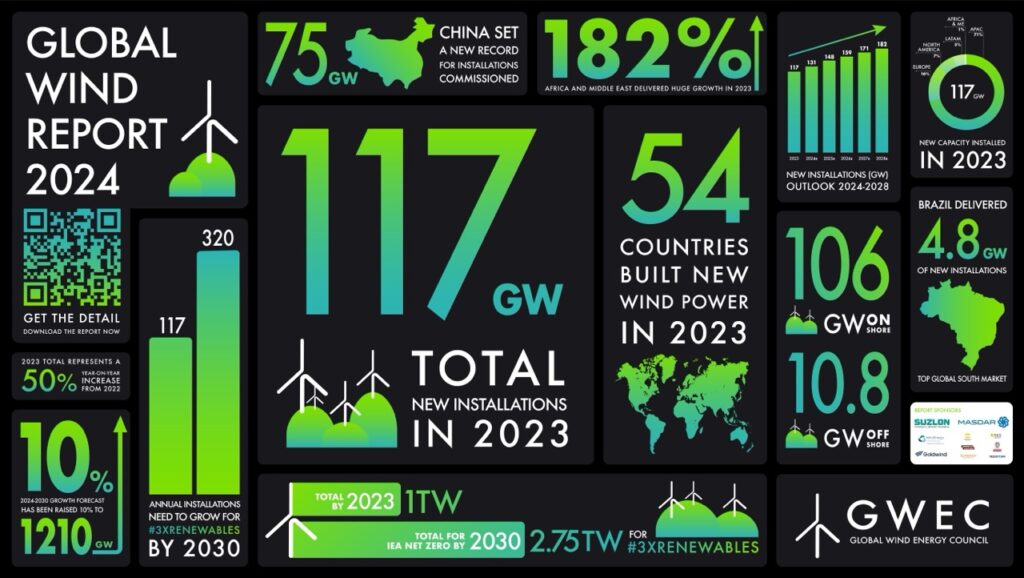

According to the Global Wind Energy Council, a record 117 GW of wind power was installed. This is a 50% increase on wind power installed in 2022. The bulk of the installations (~90%) have been onshore turbines. 75 GW of this has been installed in China. Over the next six years, an additional 1200 GW of wind power is projected to be installed.

Turbines have been steadily increasing in size over the last 20 years with hub heights doubling during this time. The average rotor diameter is now around 130 m, up from 100 meters 10 years ago. This has meant that the electrical capacity of the turbines has increased by 70% over the last decade. This in turn has reduced the levelized cost of energy (LCOE) by around 60% over this period. Currently, based on LCOE, wind energy is one of the cheapest forms of energy generation.

Issues with Wind Power

The main issues for wind power are the remote locations of high-quality wind resources (leading to longer transmission lines) and the effect on wildlife through collisions. Although not much can be done about the location of high-quality wind resources, cut-in speeds can be increased to reduce the number of collisions. Cut-in speeds of turbines are the speed at which they start to turn. For most turbines this is around 3 to 3.5 m/s of wind speed. By increasing the cut-in speed to 4.5 to 5 m/s this drastically reduces the number of bat and bird strikes. Bats are most active during periods of low wind. This change in the cut-in speed has been shown to have minimal effect on the revenue from wind turbines.

Wind turbines and extreme weather

At higher wind speeds, turbines will have a cut-out speed to protect the turbine. This is usually around 25 m/s. A brake will be applied, the rotor will be turned perpendicular to the wind or airflow will be diverted by moving the blade themselves (known as feathering). Feathering has the advantage that the turbine will still produce power. The survival speed for turbines is the maximum wind speed the turbine can face without being damaged. Survival speeds for most turbines are around 60 m/s. However, larger turbines can have higher survival speeds above 80 m/s.

With an increase in strong wind events due to climate change, wind turbines that can better survive extreme weather events are being developed. These developments include turbines which remain operational during cyclones and typhoons, meaning more wind energy can be harvested. The Japanese company Challenergy is developing a vertical axis wind turbine specifically designed to withstand typhoons and harness power from them.

Sustainability of wind turbines

Wind turbine sustainability needs to consider the lifecycle cost of the power system. However, the very conditions faced by wind turbines mean that componentry, especially the blades, are at risk of failure. Towers can topple and blades can crack due to extreme weather (like lightning strikes) or mechanical failure. Most parts of a wind turbine (e.g. the nacelle and tower) are recyclable. However, wind turbine blades, which are made of composite materials, have traditionally been sent to landfill. Blades can measure up to 130 m in length, weigh up to 40 tons and have a design life of around 20-25 years.

Wind turbine sustainability needs to consider the ultimate fate of wind turbine waste. There is expected to be 43 million tons of blade waste generated by 2050. Therefore increasing attention is being paid to recycling existing wind turbine blades and developing new blades which are easier to recycle at end of life. Recycling methods that have been developed for existing composite blades includes using them as construction filler following mechanical processing. Additionally, chemical solvents are used to break down the blade resins to allow for them to be reused in the manufacture of new blades. Wind turbine manufacturers are also developing new blade materials that are fully recyclable. For example, Siemens Gamesa’s RecyclableBlade is made from a new resin that is easier to separate at the end of life.

Image Credit: Siemens Gamesa

Moerk Water uses wind power to operate water treatment systems, so are very interested in developments in wind power. Contact Moerk Water to find out more about wind powered water treatment.